steam leak and steam trap audit

This is the fact that the demand for energy will never decrease, in fact, it will definitely rise with enhanced standard of living. Thus looking at this situation Industries must have energy management system to come together to set new standards that can aid enhanced energy management.

We ENEFIN (ENERGY EFFICIENCY AND INTELLIGENCE) our enhanced steam management system (ESMS) brings effective and reliable monitoring edge over the other traditional methods with best ways to cut down the energy waste.

WHY WE NEED TO PERFORM A STEAM LEAK AND TRAP AUDIT……

Steam is one of the most expensive utilities for the manufacturing plants. Effective maintenance on a steam system is very essential to ensure high product quality and longevity of the steam reticulation system.

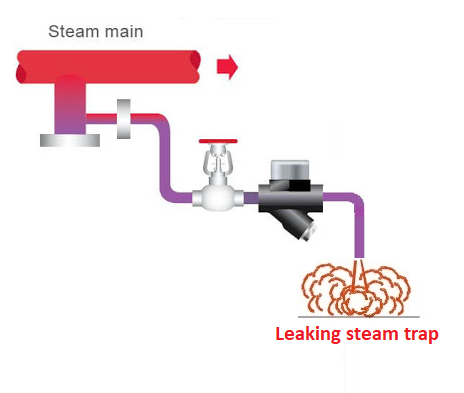

One specific area that requires ongoing maintenance are steam traps. Leaking steam traps waste energy, affect product quality, waste water, and adversely affect the environment, the main purpose of a steam trap is to remove condensate, air, and non-condensable gasses from the system while minimizing the loss of steam. When steam traps fail, they may not shut your facility down immediately, but they can negatively affect your process and increase your energy consumption significantly. If defective or leaking traps are not identified and corrected, around 20% of the steam generated at the boiler can be lost throughout the system. Take a look at the operating costs for your steam system. A 20% decrease is almost sure to provide significant savings and a great story for your facility, maintenance department, and reliability team.

ENEFIN (ENERGY EFFICIENCY AND INTELLIGENCE) we believe a proper steam trap maintenance program is essential to a steam system. Defective steam traps not only waste energy, they contribute to pipe corrosion due to poor water quality and contaminants allowed to pass downstream. Defective steam traps can adversely affect product quality in numerous manufacturing processes and even add to environmental pollution. It is important to inspect steam traps regularly by conducting a steam trap survey.

Our systems experts will cover entire plant during our steam leak and steam trap audit we will identify and classify the leakage based on the severity, high cost and ease of repair.

As part of our audit, we prefer to keep good understanding of the system is essential before inspection starts, drawings with all the steam traps and valves in a facility will be very useful. During our audit all traps be tagged and referenced on the drawings. In addition, the steam trap information on the trap type, manufacturer, and application will be recorded to increase steam trap survey effectiveness, it is recommended that historical record keeping and data collection be employed to receive information about the steam system over time. This is useful not only to account for savings realized but for spotting potential areas of recurrent problems

ENEFIN we submit a detailed comprehensive audit report including recommendations for correcting the inefficiencies our team identifies within the steam system. The report (blueprint) is extensive and the identified inefficiencies including photos, energy loss estimate, recommended equipment and solutions